Made

for making

your job easier

Advantage is 100% warranty we give to our products for delighting our customers.

We believe in results and perfection of our tools. We love creativity in gardening and cherishing the fact that environment affects the way we feel and see the world. We definitely make it more beautiful, more enjoyable with our gardening tools and positively impacting our well-being tremendously. Therefore, we got your back in any gardening activity with MY TOOLS.

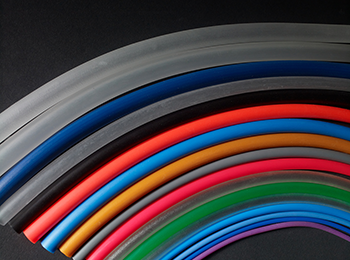

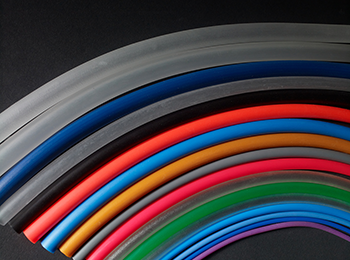

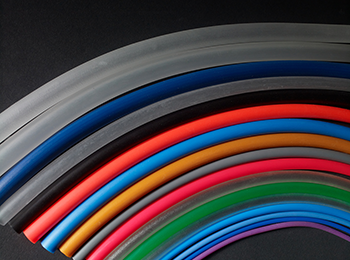

When we come to a decision moment what material should we use for our tools, it is important to understand all the possible options. Traditionally tool handles were made of plastic, rubber or had both components. Thermoplastic Elastomers that are also called thermoplastic rubber (TPR) are materials that repeatedly soften/melt when heated and harden when cooled. The first thermoplastic elastomer (TPE) became available in 1959 and since this time a plethora of new variations of such materials has become available.

When we come to a decision moment what material should we use for our tools, it is important to understand all the possible options. Traditionally tool handles were made of plastic, rubber or had both components. Thermoplastic Elastomers that are also called thermoplastic rubber (TPR) are materials that repeatedly soften/melt when heated and harden when cooled. The first thermoplastic elastomer (TPE) became available in 1959 and since this time a plethora of new variations of such materials has become available.

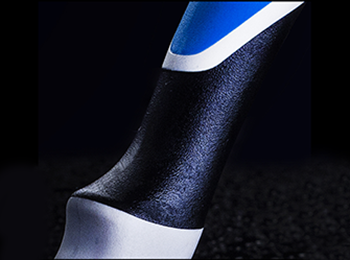

For high quality hand tools we need to make sure that all the criteria are met: rubbery appearance and feel, wide range of density, consistency of product, design flexibility, weathering resistance, fluid resistance to acids, bases, and other aqueous based fluids. We also care about the environment. TPE can be melted, repeatedly deformed, and recycled.

In the course of several product innovations, TPE are increasingly replacing standard plastics and conventional elastomers. Due to far-reaching options for combination of elastic and thermoplastic phases, TPE are among the most dynamically developing materials.

Manufacturers increasingly use TPE due to the significant cost savings possible because their ability to be processed on plastics machinery. Conventional rubber, whether natural or synthetic, is a thermosetting material that must undergo a chemical cross-linking reaction during moulding or extrusion, typically called curing or vulcanization. Due to this reaction it is not generally processable in standard thermoplastic equipment. The time that it takes for the vulcanization reaction to complete is influenced by many factors, however it is typical that this is somewhere between 1 minutes and several hours. The thermoplastic moulding and extrusion processes used for TPEs, on the other hand, avoid the cross-linking step and can achieve very fast cycles times, which can be as little as 20 seconds.

Thermoplastic Elastomers add tactile and visual enhancement and provide a functional performance such as resistance to skin oils. Therefore these materials offer the ability to enhance the quality of most professional hand tools.

When we come to a decision moment what material should we use for our tools, it is important to understand all the possible options. Traditionally tool handles were made of plastic, rubber or had both components. Thermoplastic Elastomers that are also called thermoplastic rubber (TPR) are materials that repeatedly soften/melt when heated and harden when cooled. The first thermoplastic elastomer (TPE) became available in 1959 and since this time a plethora of new variations of such materials has become available.

For high quality hand tools we need to make sure that all the criteria are met: rubbery appearance and feel, wide range of density, consistency of product, design flexibility, weathering resistance, fluid resistance to acids, bases, and other aqueous based fluids. We also care about the environment. TPE can be melted, repeatedly deformed, and recycled.

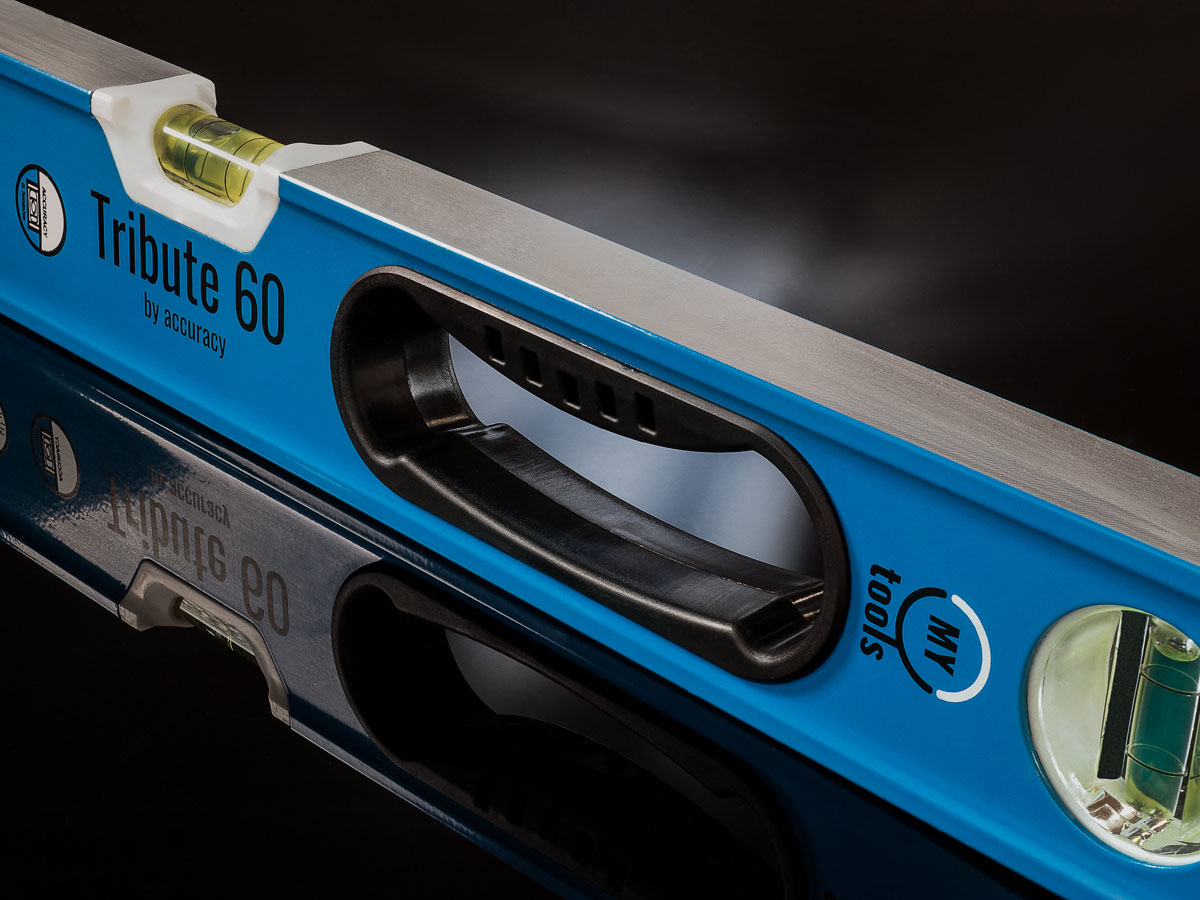

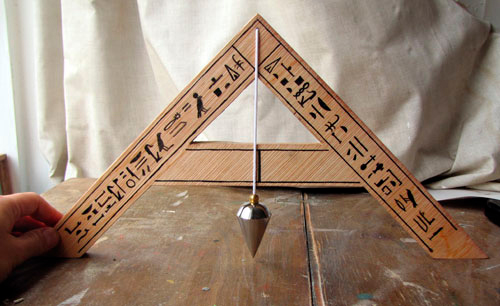

Throughout history of all civilization, people have built more and more complex designs and constantly faced with the need to put their parts exactly horizontal or vertical. People learned how to use the basic laws of physics very quickly. Simple plumbs, i.e. loads, hanging by a thread, always gave a fairly accurate vertical, and the flexible tube filled by water with ends facing up was used as a simple water level. It is not exactly known what the Egyptians, who built the pyramids, used, but we can assume that the people who were able to build these magnificent buildings, have learned how to use these simple tools.

Throughout history of all civilization, people have built more and more complex designs and constantly faced with the need to put their parts exactly horizontal or vertical. People learned how to use the basic laws of physics very quickly. Simple plumbs, i.e. loads, hanging by a thread, always gave a fairly accurate vertical, and the flexible tube filled by water with ends facing up was used as a simple water level. It is not exactly known what the Egyptians, who built the pyramids, used, but we can assume that the people who were able to build these magnificent buildings, have learned how to use these simple tools.

The first spirit level was invented by Melchisedech Thevenot (1620–1692) — rich scientist mathematician from France. He described the construction of such device in the letters to other scientists from London and Florence. Such levels were first appeared in France and gradually spread to other countries. Early spirit levels had a glass flask with a constant inner diameter and a small curvature. This curvature naturally possessed an air bubble at the top at the center of the flask. Later, flasks was made in the form of «barrel» with the slightly larger middle diameter than the diameter at the edges. It made it possible to use the level in the inverted position.

Alcohols such as ethanol was used as the filling. Alcohols have low viscosity and surface friction coefficient that allow the bubble to move freely . Alcohol also has much wider liquid temperatures range, they do not freeze in the flasks and do not split them. They also began to add dyes in liquid for more bubble contrast, sometimes fluorescent.

The next stage of the spirit level was the «bull’s eye» level — round-shaped flask with a flat bottom and slightly curved glass surface. It operates on the entire surface, while the traditional bulb only ensures alignment its axis.

In today’s levels there were many improvements that make this tool as a complex technological device. There are shock levels, designed to work with tile or stone, a variety of designs which facilitate review of the vertical flasks, instrument protection against hits, drops and other impacts. But the basic principle of operation is still unchanged since its invention.

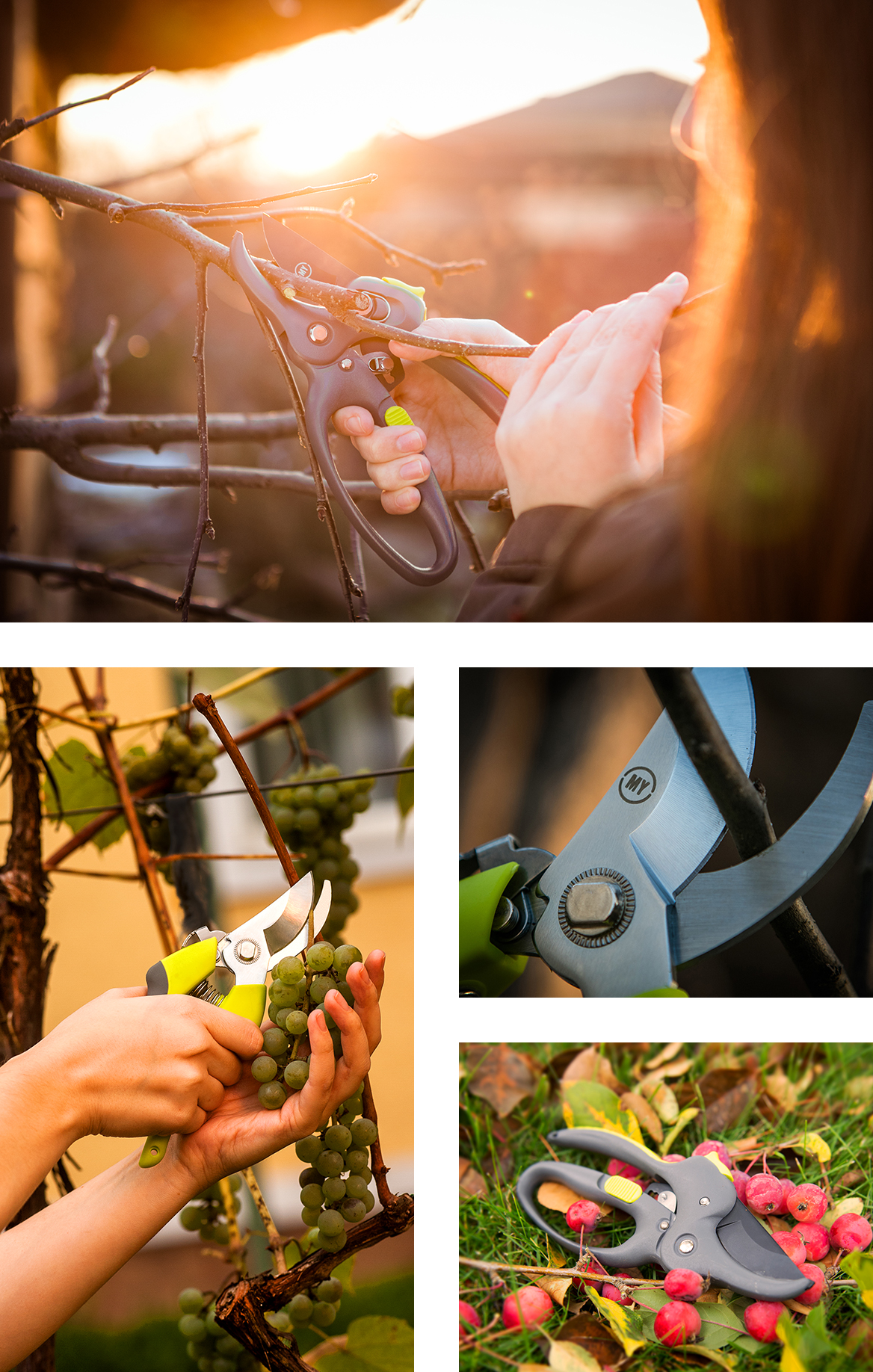

Garden shears are one of the most important tools of different garden tools. When properly used, it is this simple device that has an effect on harvesting, health and visual appearance of plants, and what is the most important, it has an effect on mood and emotions of a gardener working with the tool. Many people believe that garden shears are the tool of rather restricted application that can be used only seasonally, in a limited period of a year. But that is not always true. Without any doubt, garden shears can be named the most functional tool of all the tools used for garden work. Garden shears can be used throughout the year for fruit trees, ornamental trees, berry beds, hedges, flower gardens, and vineyards. Let’s go through the operations that are necessary to conduct for maintaining your garden in a good condition, both in fruit-bearing and in visual appearance.

Garden shears are one of the most important tools of different garden tools. When properly used, it is this simple device that has an effect on harvesting, health and visual appearance of plants, and what is the most important, it has an effect on mood and emotions of a gardener working with the tool. Many people believe that garden shears are the tool of rather restricted application that can be used only seasonally, in a limited period of a year. But that is not always true. Without any doubt, garden shears can be named the most functional tool of all the tools used for garden work. Garden shears can be used throughout the year for fruit trees, ornamental trees, berry beds, hedges, flower gardens, and vineyards. Let’s go through the operations that are necessary to conduct for maintaining your garden in a good condition, both in fruit-bearing and in visual appearance.

Traditionally, let’s start with spring works. Of course, in the first place, you have to conduct trees trimming, both forming and sanitary, as during winter some tree branches could get frozen or get broken under the weight of snow. The same goes for bushes and vineyard especially if you have plant sorts that remain unsheltered in winter, on summerhouses or on fruit-frames. In case you want to add something new by means of graftage — garden shears will make work easier. By the end of May, it is necessary to remove the first generation of sprouts before they make tree crown too thick depriving growing fruits of light and nutritional substances. All kinds of ornamental perennial plants, from roses to cording and separate geometric boxwood groups. In summer, we have to deal with such routine work as sanitation pruning (some tree branches get dry and damaged by vermins), work with buds, disbudding, and trimming of vine. In July, the second generation of sprouts appears, and it also has to be removed timely. Then, as autumn comes, we move to autumn work without haste. Once again, tree crowning-off, work in vineyard, cutting of everbearing raspberry for winter. For the sake of time and effort saving, some part of pruning work can be done in winter. Another year begins.

I am sure there are skeptics who will say that the topic of sprouts has not been covered completely. All in good time. We’ll have other opportunities to go through the range of season garden works and operations in more details. It is undeniable fact that garden shears are important for garden work. One of the key factors is the time you spend working in the garden, or at backyard. What we try to achieve is to transform this work time into pleasure time. Our customer is the one who considers garden work as a good time, as one of their hobbies, as part of their life.

Garden shears are one of the most important tools of different garden tools. When properly used, it is this simple device that has an effect on harvesting, health and visual appearance of plants, and what is the most important, it has an effect on mood and emotions of a gardener working with the tool. Many people believe that garden shears are the tool of rather restricted application that can be used only seasonally, in a limited period of a year. But that is not always true. Without any doubt, garden shears can be named the most functional tool of all the tools used for garden work. Garden shears can be used throughout the year for fruit trees, ornamental trees, berry beds, hedges, flower gardens, and vineyards. Let’s go through the operations that are necessary to conduct for maintaining your garden in a good condition, both in fruit-bearing and in visual appearance.